To Form “Expansion” Movement Joints with Tec-Form

Suggested uses for Tec-Form with “Expansion” movement joint, i.e. the opposing screeds or slabs are not fixed in position, and can move to accommodate thermal expansion, usually with the use of “Dowel Bars and Sleeves”, usually made from smooth round steel re-bar with plastic sheaths:

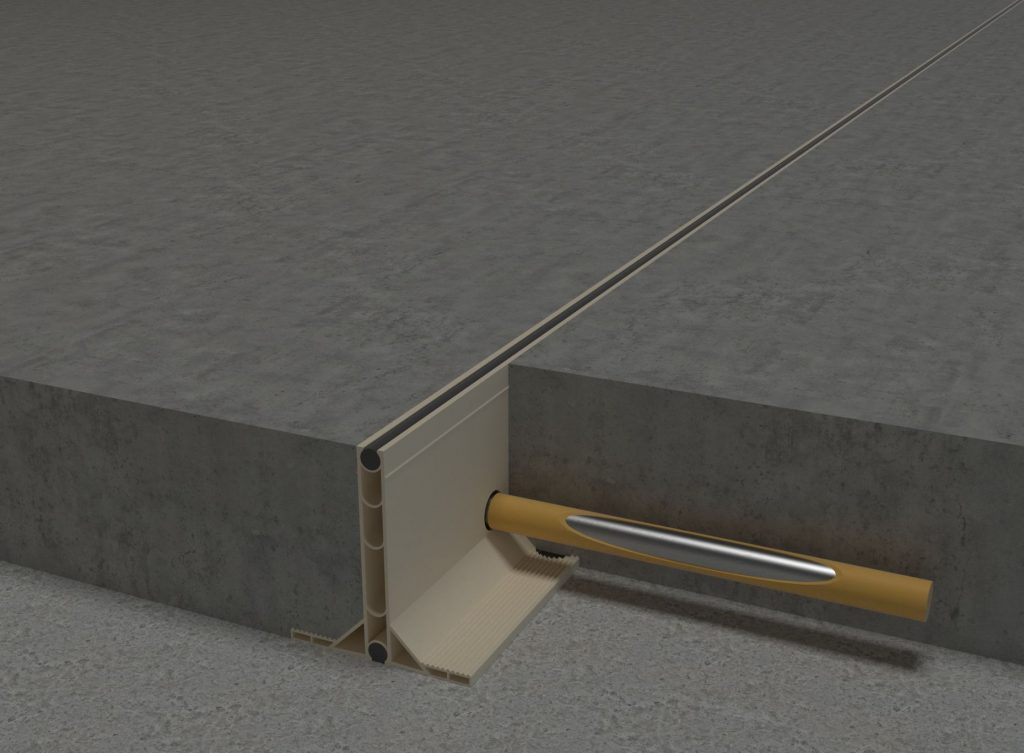

For a basic screed or slab with expansion movement joint, the exposed compressible insert can be taped over or covered to prevent staining or ingress of screed material.

The base rail can be used, with the compressible inserts to accommodate the closure of the joint gap due to thermal expansion of the screeds or slabs, tapes or covers can be removed after installation for aesthetics.

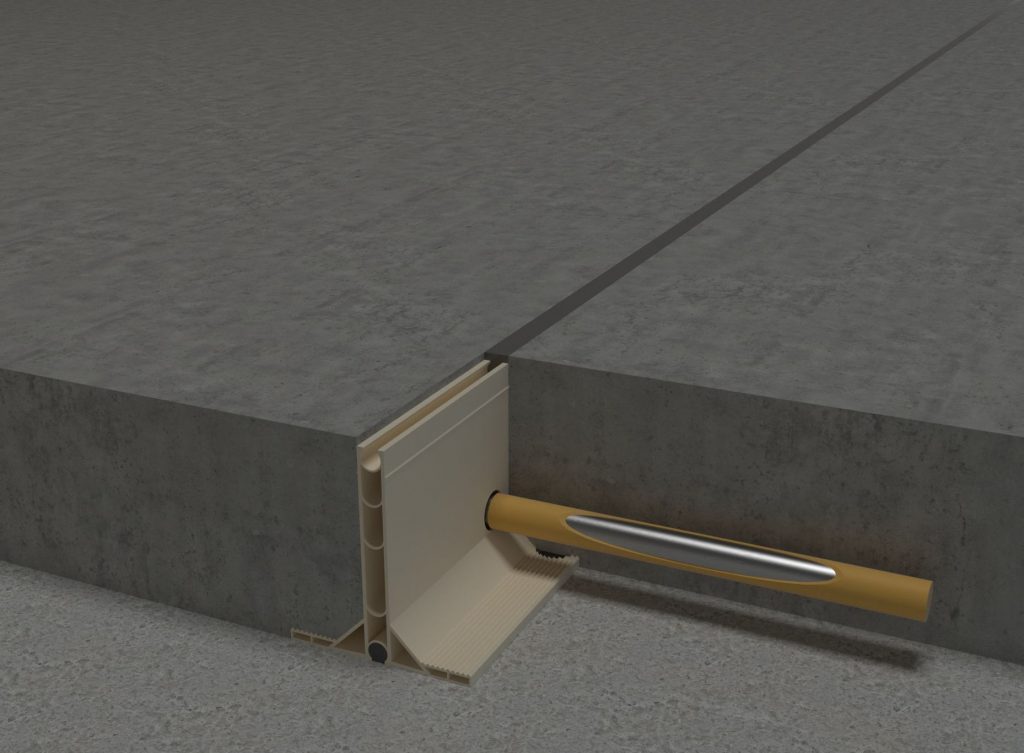

For screeds or slabs with expansion movement joints, where the joint has to be filled for aesthetic or hygienic requirements.

The base rail can be used, with either a top cap (re-useable) or compressible insert, which can be removed after installation. The resulting rebate formed will be filled with the flexible joint filler material, supporting the joint arrises and effectively replacing the compressible insert.

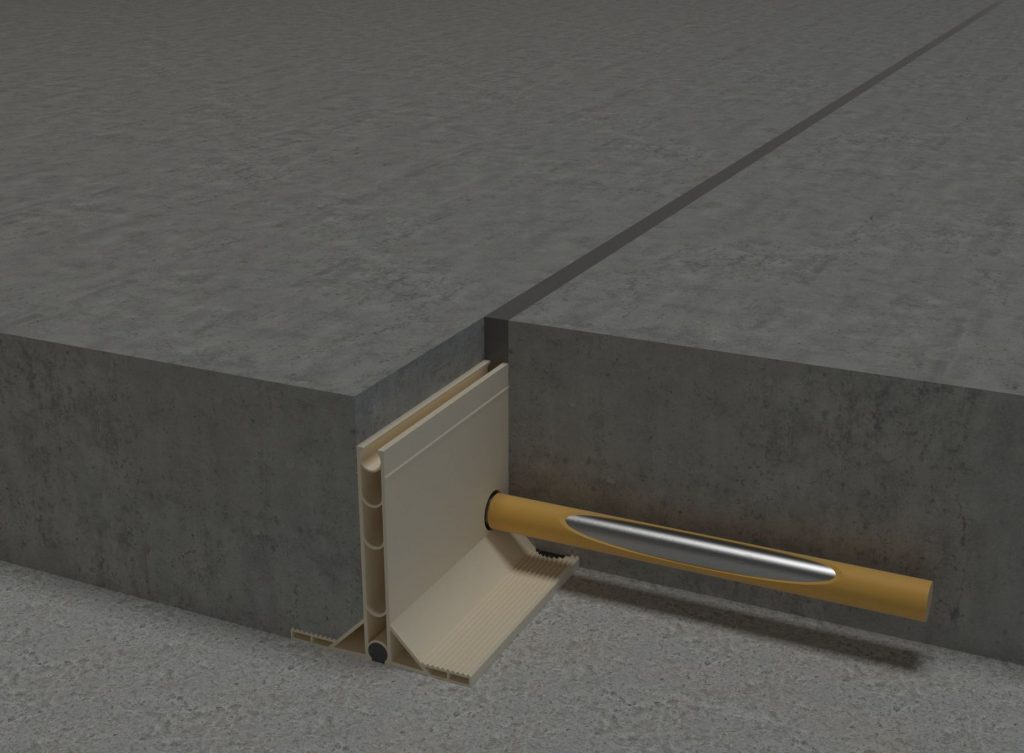

For screeds or slabs with expansion movement joints, where the joint has to be deep filled for safety or hygienic requirements.

The base rail can be used, with a top extender strip (re-useable), which can be removed after installation if required. The resulting 25mm deep rebate formed, can be filled with a proprietary joint filler as required.

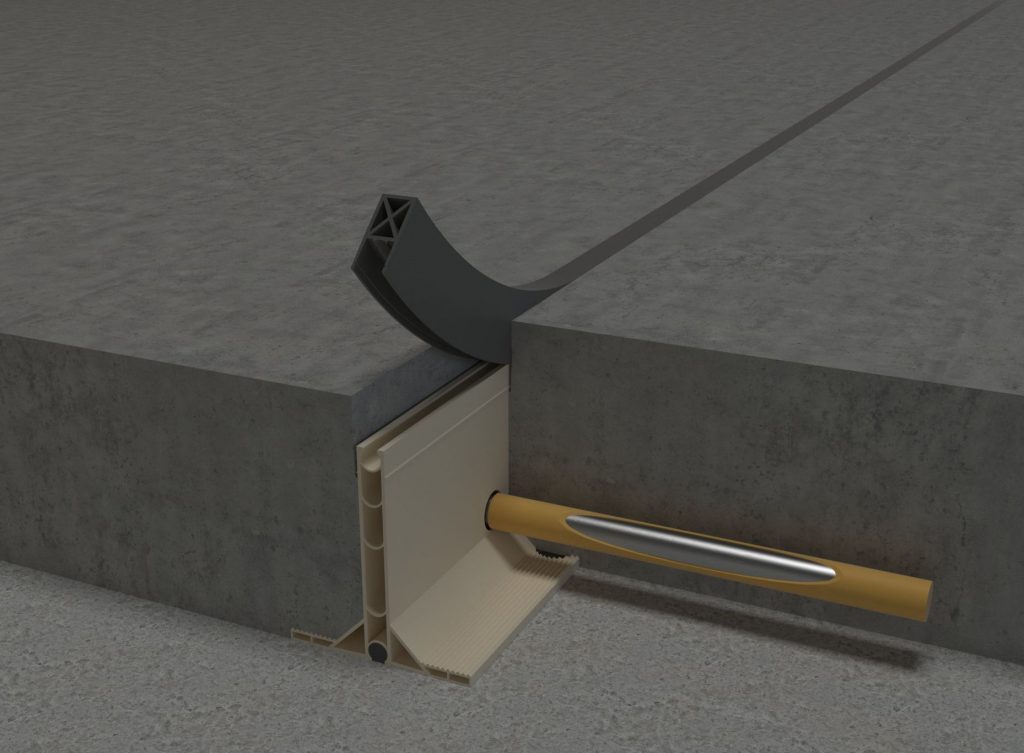

For screeds or slabs with expansion movement joints, where the base rail has to be extended to suit a specific depth.

The base rail can be used, and extended in height with a push on Top Extender (25mm), as shown previously, this extender can be removed after installation if required, or simply left in situ.